Ensuring that your 19 HP Kawasaki engine runs smoothly and efficiently is critical for the long-term performance and reliability of your equipment. One of the most essential components in maintaining this efficiency is the starter system. By using the 21153-7010 16121 starter rebuild kit, you can restore the starter system to its original condition, ensuring consistent and reliable engine performance. In this expanded guide, we’ll walk you through each step of the rebuilding process while highlighting key maintenance tips that will help extend the life of your rebuilt starter system.

Why the Starter System Matters in Your Kawasaki Engine

The starter system is the heart of your Kawasaki engine’s ignition process. Whether you’re using your engine in a lawnmower, tractor, or other machinery, the starter plays a pivotal role in making sure the engine begins running smoothly. The starter engages the flywheel, initiating the combustion process necessary for engine operation. Without a functioning starter, the engine simply won’t work.

Over time, starters are subjected to wear and tear, particularly if the engine is used frequently. Common issues such as slow cranking, strange noises, or a complete failure to start are often signs of a worn-out starter. Fortunately, with the 21153-7010 16121 starter rebuild kit, you can replace the worn components and restore your engine’s starting capability. Rebuilding the starter not only extends the life of your engine but also saves you from costly repairs or the need to buy a new engine.

Key Signs That Indicate a Starter Rebuild is Needed

Recognizing the early signs of a failing starter is crucial to preventing further damage to your Kawasaki engine. If you catch the issues early, a starter rebuild using the 21153-7010 16121 starter rebuild kit can save you time and money. Here are the most common signs that signal your starter may need rebuilding:

- Slow Engine Start: If your engine takes longer than usual to start or requires several attempts, it’s likely that the starter is losing power or has internal wear that’s affecting its performance.

- Unusual Noises: Clicking, grinding, or whirring sounds during startup are clear indicators that there’s something wrong with the starter mechanism. These noises often point to damaged gears, brushes, or bearings inside the starter.

- Intermittent Operation: If the starter sometimes fails to engage or works only intermittently, this suggests a more serious issue. In this case, the internal components might be damaged or the electrical connections are compromised, requiring an immediate rebuild using the 21153-7010 16121 starter rebuild kit.

Overview of the 21153-7010 16121 Starter Rebuild Kit Components

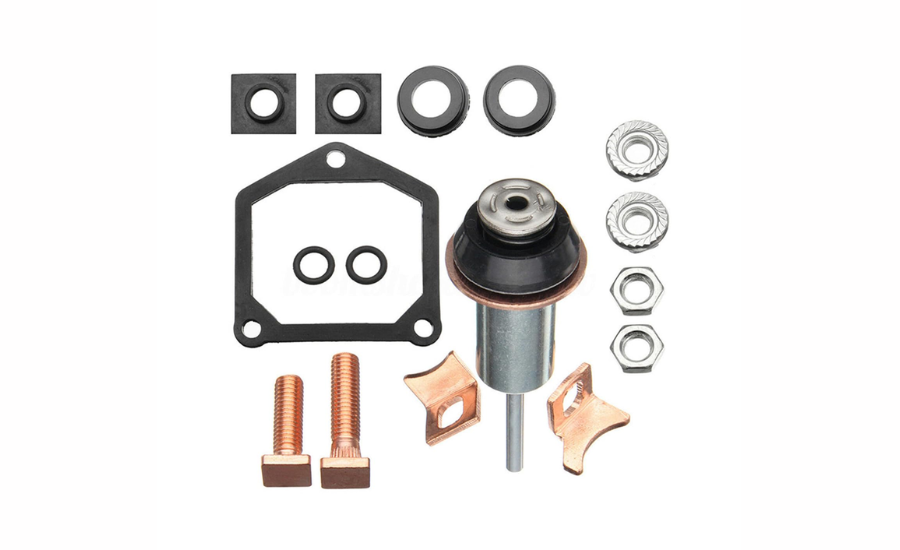

The 21153-7010 16121 starter rebuild kit is designed to include all the essential components needed to restore the starter to its peak performance. Each part in the kit plays a specific role in ensuring that the starter works smoothly, reducing friction, and improving electrical connectivity. Let’s explore what’s inside the rebuild kit:

- Brushes: These are essential for conducting electrical current to the starter motor. Worn-out brushes are one of the most common causes of starter failure. Replacing them with new ones from the kit ensures reliable performance.

- Bushings and Bearings: These components reduce friction between moving parts and provide essential support. Worn bearings or bushings can cause misalignment or even seize the starter, making them critical to replace.

- Seals: Seals prevent dirt, moisture, and debris from entering the internal components of the starter, ensuring a clean operating environment.

- Springs and Retainers: These maintain proper tension and positioning of the brushes, which ensures a consistent electrical connection.

- Hardware: The kit also includes screws, washers, and other fittings required for reassembly. Using fresh hardware ensures a secure rebuild without the risk of loose connections or components.

Step-by-Step Process to Rebuild the Starter

Rebuilding your starter using the 21153-7010 16121 starter rebuild kit may seem daunting, but following this step-by-step process will guide you through the entire procedure with ease.

Gathering Tools and Disassembling the Starter

For this task, you’ll need a socket set, screwdrivers, pliers, a torque wrench, and safety equipment such as gloves and safety goggles.

- Removing the Starter: Start by disconnecting the battery to prevent any accidental electric shocks. Next, locate the starter on your engine and carefully remove the bolts securing it. Detach any necessary electrical connections before fully removing the starter from the engine.

Cleaning and Inspecting the Parts

A thorough cleaning is critical for ensuring a successful rebuild. Use a suitable solvent to remove dirt, oil, and debris from each component of the starter.

- Inspection: After cleaning, inspect the armature, solenoid, gears, and other moving parts for signs of wear or damage. Pay close attention to the brushes and bearings, as these parts often degrade over time. Replace any damaged or excessively worn components using the parts included in the 21153-7010 16121 starter rebuild kit.

Replacing Worn-Out Components

The 21153-7010 16121 starter rebuild kit comes with high-quality replacement parts that restore your starter to like-new condition.

- Brushes and Bearings: Start by replacing the worn brushes and bearings. These are critical for maintaining smooth electrical conductivity and reducing friction within the starter.

- Seals and Bushings: Replace the old seals and bushings with new ones from the kit to protect the internal components and ensure a smooth, tight fit during operation.

Reassembling the Starter and Testing

Once all the worn-out components have been replaced, it’s time to reassemble the starter. Follow the reverse steps of disassembly, ensuring that all parts are securely fastened and aligned correctly.

- Testing the Starter: After reassembly, reconnect the battery and test the starter. If the starter engages smoothly and starts the engine without any noise or hesitation, your rebuild has been successful.

Tips for Maintaining Your Rebuilt Starter for Longevity

After completing the rebuild using the 21153-7010 16121 starter rebuild kit, maintaining your starter is crucial for extending its lifespan and ensuring consistent performance.

- Regular Inspections: Perform routine inspections of the starter and its electrical connections to detect any signs of wear, corrosion, or loosened fittings. Addressing small issues early can prevent major failures later.

- Clean Electrical Connections: Dirt, grease, and moisture can negatively impact electrical conductivity. Keep all electrical connections clean and tight to avoid performance problems.

- Limit Short Starts: Frequently starting your engine for short trips can wear out the starter more quickly. Try to limit unnecessary starts to prolong the life of your starter.

FAQs About 21153-7010 16121 starter rebuild kit

Q: How often should I rebuild my starter?

A: The frequency of starter rebuilds depends on usage. If you notice symptoms such as slow starts or unusual noises, it’s time for a rebuild. Regular maintenance checks can also help you identify issues before they escalate.

Q: Can I use any starter rebuild kit for my Kawasaki engine?

A: It’s crucial to use the correct rebuild kit, like the 21153-7010 16121, which is specifically designed for your engine model. Using the wrong kit may lead to improper fit or functionality, potentially causing further damage.

Q: Is it difficult to rebuild the starter myself?

A: While it requires some mechanical skills, rebuilding the starter is manageable for those comfortable with basic tools and engine maintenance. The step-by-step guide provided can help you through the process.

Q: What if I encounter issues during the rebuild?

A: If you encounter any problems or feel unsure at any stage, consult the starter kit instructions or seek assistance from a professional mechanic. It’s better to ask for help than to risk damaging your engine.

Conclusion

Rebuilding the starter system of your 19 HP Kawasaki engine with the 21153-7010 16121 starter rebuild kit is an effective way to ensure reliable engine performance and save on future repair costs. By identifying early signs of starter failure—such as slow starts, unusual noises, or intermittent operation—you can take proactive measures to address these issues. The rebuild kit provides essential components like brushes, bearings, seals, and hardware, simplifying the restoration process. By following the step-by-step guide for disassembly, cleaning, component replacement, and reassembly, you can successfully complete the rebuild. Regular inspections and proper maintenance practices will further extend the life of your rebuilt starter, allowing your Kawasaki engine to run smoothly for years to come. Investing time and effort into this rebuild not only enhances performance but also helps you avoid costly repairs down the line.

Read Next: netwyman-blogs